Ntrogen generator quality nitrogen generating equipment psa gas nitrogen generator equipment for chemical industry

Working principle

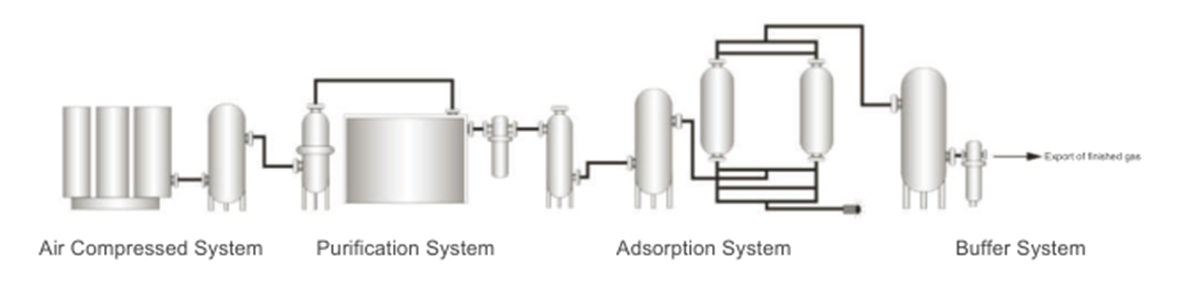

When the air pressure rises, the carbon molecular sieve will absorb a large amount of oxygen, carbon dioxide and moisture. When the pressure drops to normal pressure, the adsorption capacity of carbon molecular sieve to oxygen, carbon dioxide and moisture is very small.

The pressure swing adsorption generator is mainly composed of two adsorption towers A and B equipped with carbon molecular sieves and a control system. When the compressed air (the pressure is generally 0.8MPa) passes through tower A from bottom to top, oxygen, carbon dioxide and water are adsorbed by carbon molecules, while nitrogen is passed through and flows out from the top of the tower. When the molecular sieve adsorption in tower A is saturated, it will switch to tower B to carry out the above adsorption process and regenerate the molecular sieve in tower A at the same time. The so-called regeneration is the process of evacuating the gas in the adsorption tower to the atmosphere, so that the pressure quickly returns to normal pressure, and the oxygen, carbon dioxide and water adsorbed by the molecular sieve are released from the molecular sieve. The PSA nitrogen generator technology is a high-tech energy-saving separation technology that directly produces nitrogen from the air at room temperature, and has been applied for decades.

Process flow chart

Qualification certificate

Company Pictures

Video

Technical indicators

|

Nitrogen Flow |

3-3000Nm³/h |

|

Nitrogen Purity |

95%-99.999% |

|

Nitrogen Pressure |

0.1-0.8 MPa (adjustable) |

|

Dew Point |

-45~-60℃(under normal pressure) |

|

|

|

Technical characteristics

1. Adopt new oxygen production process, constantly optimize device design, reduce energy consumption and investment capital.

2. intelligent interlocking oxygen emptying device to ensure the oxygen quality of products.

3. unique molecular sieve protection device, prolong the service life of zeolite molecular sieve.

4. perfect process design, optimal use effect.

5. optional oxygen flow, purity automatic regulation system, remote monitoring system, etc.

6. simple operation, stable operation, high degree of automation, can realize unmanned operation.

After-sales maintenance

1.Each shift regularly check whether the exhaust muffler is emptied normally.

2.Exhaust silencer such as black carbon powder discharge indicates that carbon molecular sieve powder, should be shut down immediately.

3. Clean the dust and dirt on the surface of the equipment.

4. Check the inlet pressure, temperature, dew point, flow rate and oil content of compressed air regularly Normal.

5. Check the pressure drop of the air source connecting parts of the control air path.