JXX high efficiency oil remover

Product introduction

Degreaser science to set screw separation, pre filtering and condensing type fine filtration tertiary purification is an organic whole, can be effective in addition to water, oil removal, dust filtering, to shorten the purification process of compressed air, then through post-processing of the precision filter, the filtering precision can reach 0.1 um, residual oil content can be less than 0.03 mg/Nm3, air purification quality get the reliable guarantee.

The product adopts our company's newly developed and elaborately made filter element, which is characterized by compact structure, small volume, high purification efficiency, convenient replacement and installation, and fundamentally ensure the use effect.

Working principle

The high-efficiency oil remover is composed of upper and lower barrel bodies, middle tray, spiral separator, pre-filter assembly, fine filter assembly, instrument and sewage assembly (not shown in the picture), etc.The compressed air containing a large number of suspended particles, water and oil enters the lower cylinder first, and the liquid oil and water are deposited at the bottom by spiral separation, discharged by the sewage assembly, and the air flows into the pre-filtration assembly to remove large solid and liquid particles.Finally gas from entering the core components of the degreaser - fine filter, gas through the combination of the filter bed interception, collision, such as diffusion, gravity sedimentation effect, make the tiny oil, water aerosol particles in the process of wear filter bed was set in their microfiber junctions condensation, and gradually grew up, eventually achieve gas-liquid separation in the gravity settling layer, so as to get clean, no oil, no water, Dust-free) compressed air.

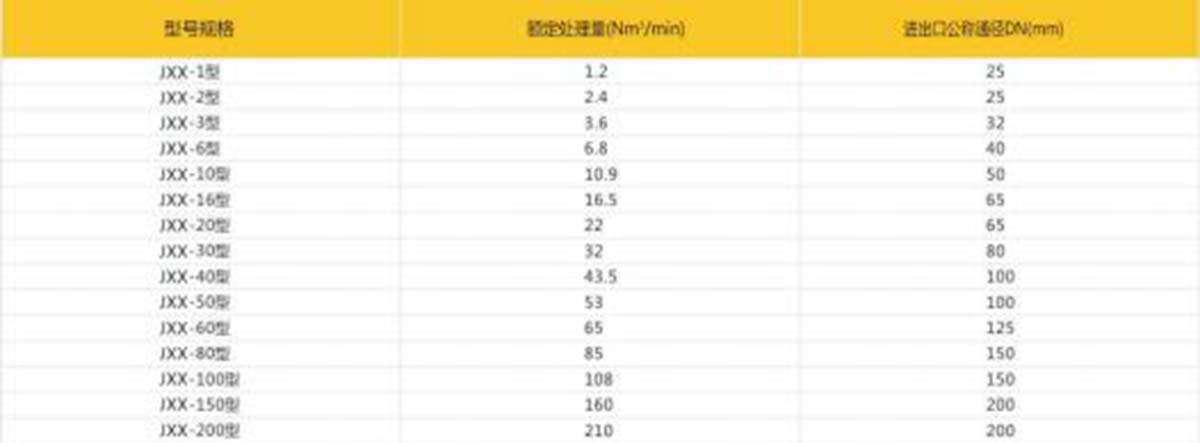

Technical indicators

| Working pressure | 0.6-0.1mpa (1.0-3.0mpa upon request) |

| Inlet temperature | ≤50℃ |

| Output oil content | < 0.1-0.01ppm |

| Pressure loss | ≤ 0.02mpa |