Hospital Containerized Oxygen Generator PSA Medical Oxygen Production Plant

Brand:JUXIAN

Certification: ISO9001-2016, ISO14001-2015, ISO45001-2018, ISO13485

After-Sale Service:Lifetime tech support & Dispatch Engineer & Video Meeting

Warranty:1 Year, lifetime technology support

Advantages: Compact generator, fully automatic operation, low operating cost, less maintenance, no environmental pollution

Service: OEM & ODM

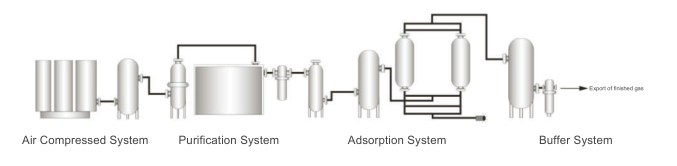

Process flow chart

Working principle

According to the principle of PSA pressure swing adsorption, the oxygen production equipment is carefully developed, and the high-quality oxygen production zeolite molecular sieve is used as the adsorbent to directly separate and produce oxygen from the air at room temperature. The purified and dried pretreated compressed air realizes the separation of oxygen and nitrogen under the action of pressure swing adsorption. Due to the selective adsorption characteristics of molecular sieves, nitrogen is adsorbed in molecular sieves, and oxygen and oxygen are accumulated and output as products. The system is equipped with two adsorption towers, one for oxygen production by adsorption, and one for desorption and regeneration, alternating cycles to continuously produce oxygen.

After-sales maintenance

1, each shift regularly check whether the exhaust muffler is emptied normally.

Exhaust silencer such as black carbon powder discharge indicates that carbon molecular sieve powder, should be shut down immediately.

3, clean the dust and dirt on the surface of the equipment.

4. Check the inlet pressure, temperature, dew point, flow rate and oil content of compressed air regularly Normal.

5. Check the pressure drop of the air source connecting parts of the control air path.

Technical indicators

|

Nitrogen Flow |

3-400Nm³/h |

|

Nitrogen Purity |

90%-93%(the standard is 93%) |

|

Nitrogen Pressure |

0.1-0.5 MPa (adjustable) |

|

Dew Point |

-45~-60℃(under normal pressure) |

Technical characteristics

1. Adopt new oxygen production process, constantly optimize device design, reduce energy consumption and investment capital.

2. intelligent interlocking oxygen emptying device to ensure the oxygen quality of products.

3. unique molecular sieve protection device, prolong the service life of zeolite molecular sieve.

4. perfect process design, optimal use effect.

5. optional oxygen flow, purity automatic regulation system, remote monitoring system, etc.

6. simple operation, stable operation, high degree of automation, can realize unmanned operation.

After-sales maintenance

1.Each shift regularly check whether the exhaust muffler is emptied normally.

2.Exhaust silencer such as black carbon powder discharge indicates that carbon molecular sieve powder, should be shut down immediately.

3. Clean the dust and dirt on the surface of the equipment.

4. Check the inlet pressure, temperature, dew point, flow rate and oil content of compressed air regularly Normal.

5. Check the pressure drop of the air source connecting parts of the control air path.

Qualification certificate

Company Pictures