China OEM Medical Production Supplier – JXO pressure swing adsorption air separation oxygen production equipment – Juxian

China OEM Medical Production Supplier – JXO pressure swing adsorption air separation oxygen production equipment – Juxian Detail:

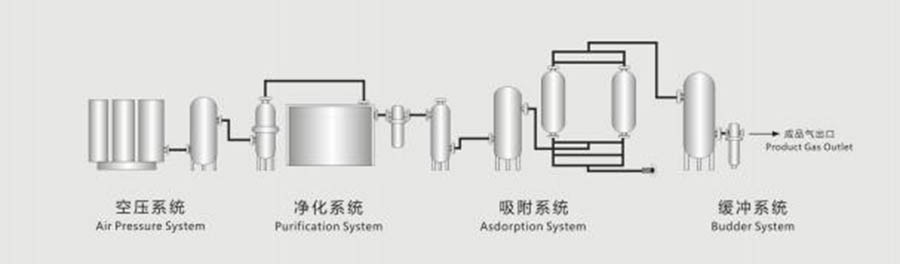

The working principle of

◆ After entering the adsorption tower with zeolite molecular sieve, nitrogen, carbon dioxide, water vapor in the air are absorbed by molecular sieve and oxygen because of large diffusion rate through the adsorbent to achieve separation.

◆ When nitrogen and other impurities adsorbed in the adsorption tower reach a certain degree, reduce the pressure to make the zeolite molecular sieve desorption, so that the adsorbent regeneration, can be reused.

Process flow chart

Technical characteristics

1. Adopt new oxygen production process, constantly optimize device design, reduce energy consumption and investment capital.

2. intelligent interlocking oxygen emptying device to ensure the oxygen quality of products.

3. unique molecular sieve protection device, prolong the service life of zeolite molecular sieve.

4. perfect process design, optimal use effect.

5. optional oxygen flow, purity automatic regulation system, remote monitoring system, etc.

6. simple operation, stable operation, high degree of automation, can realize unmanned operation.

After-sales maintenance

1, each shift regularly check whether the exhaust muffler is emptied normally.

Exhaust silencer such as black carbon powder discharge indicates that carbon molecular sieve powder, should be shut down immediately.

3, clean the dust and dirt on the surface of the equipment.

4. Check the inlet pressure, temperature, dew point, flow rate and oil content of compressed air regularly Normal.

5. Check the pressure drop of the air source connecting parts of the control air path.

Technical indicators

| Oxygen production | 3-400 nm3 /h |

| Oxygen purity | 90-93% (standard) |

| Oxygen pressure | 0.1-0.5mpa (adjustable) |

| Dew point | ≤-40~-60℃(under atmospheric pressure) |

Product detail pictures:

Related Product Guide:

Our progress depends about the advanced products ,fantastic talents and continuously strengthened technology forces for China OEM Medical Production Supplier – JXO pressure swing adsorption air separation oxygen production equipment – Juxian , The product will supply to all over the world, such as: Philadelphia, Slovenia, Adelaide, To keep the leading position in our industry, we never stop challenging the limitation in all aspects to create the ideal products. In his way, We can enrich our life style and promote a better living environment for the global community.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!