China OEM Insulating Oil Purification Quotes – JXY type waste heat regeneration dryer – Juxian

China OEM Insulating Oil Purification Quotes – JXY type waste heat regeneration dryer – Juxian Detail:

Working principle

Waste heat regenerative dryer is a new type adsorption dryer, neither belongs to the regenerative heat, also don’t belong to no heat regenerative, and belongs to the temperature swing adsorption, is the use of high temperature air compressor exhaust heat regeneration desiccant, adsorbent is completely regenerate, even in low pressure 0.35 Mpa working condition of use, as long as the compressor load rate of not less than 70%, The drying device can work reliably, so it can make full use of its own energy and has energy-saving effect.The electric heater of the micro-heat regenerative dryer is cancelled. At the same time, the waste heat regenerative compressed air dryer is a new type of energy-saving compressed air drying equipment because there is no gas consumption during heating and regeneration.

Technical indicators

| Working pressure | 1.3-1.0mpa |

| Inlet temperature | ≥100℃ |

| Finished gas atmospheric pressure dew point | ≤-40℃ (alumina) ≤-52℃(molecular sieve) |

| Control mode | microcomputer automatic control |

| Working cycle | 6-8h |

| Regenerated steam consumption | ≤2% |

Technical characteristics

1. using the world’s advanced microcomputer controller, can realize communication and linkage control, excellent performance.

2. choose high quality butterfly valve, switching quickly, accurate and reliable action.

3. the use of gas diffusion device, uniform air distribution in the tower, unique filling method, long service life of the adsorbent.

4. The regeneration process uses the waste heat of air compressor, and the regeneration energy consumption is low.

5. the overall layout is reasonable, compact structure, simple installation, convenient use and maintenance.

Waste heat regeneration air dryer technical parameters table

|

Model |

Traffic Nm3/min |

Inlet and outlet diameter mm |

Total weight kg |

Overall dimensions L * W * H mm |

Power supply/power

|

|

JXY-100/8 |

100 |

150 |

7400 |

3850 * 2260 * 3200 |

220V/50Hz 100 w or less |

|

JXY-150/8 |

150 |

200 |

10700 |

4400 * 2600 * 3500 |

|

|

JXY-200/8 |

200 |

200 |

13400 |

4900 * 2700 * 3800 |

|

|

JXY-250/8 |

250 |

200 |

17050 |

5400 * 3100 * 3820 |

|

|

JXY-300/8 |

300 |

250 |

19400 |

5900 * 3200 * 3900 |

|

|

JXY-350/8 |

350 |

250 |

22000 |

6200 * 3200 * 4360 |

|

|

JXY-400/8 |

400 |

250 |

25500 |

7100 * 2900 * 4300 |

|

|

JXY-600/8 |

600 |

350 |

36000 |

8400 * 3300 * 4760 |

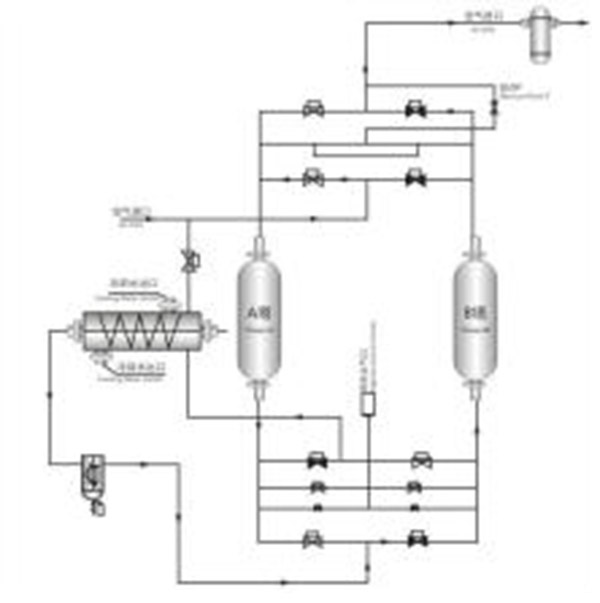

Process flow chart

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for China OEM Insulating Oil Purification Quotes – JXY type waste heat regeneration dryer – Juxian , The product will supply to all over the world, such as: Lesotho, Sweden, Latvia, Upon today, we've customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We've been looking forward to doing business with you.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!