China OEM Air Drying Equipment Quotes – JXG type blast regenerative air dryer – Juxian

China OEM Air Drying Equipment Quotes – JXG type blast regenerative air dryer – Juxian Detail:

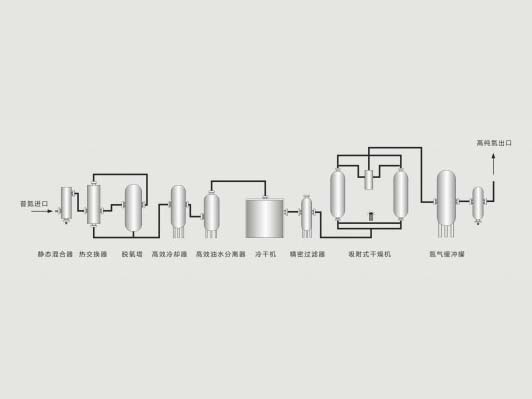

The working principle of

JXG series zero air consumption blast regeneration adsorption dryer produced by our company is a kind of energy-saving compressed air drying device. It adopts the process of environmental air blast regeneration, so it can save a lot of product gas required by traditional process regeneration.The adsorption principle of zero air consumption blast regenerative adsorption dryer is similar to that of traditional micro-thermal/non-thermal adsorption dryer.But its regeneration method is the blast regeneration process, process steps include heating, blowing cold.During heating, the regenerative air source comes from the ambient air after the blower pressure boost, and is heated to the regenerative temperature by the heater as the recycled gas resolved by the adsorbent.In the regeneration operation, the regeneration heating gas is used to heat the adsorption bed, and the water vapor precipitated by the regeneration gas is carried out and carried out of the adsorber.Regenerative air conditioning also uses ambient air for air circulation cooling separation as regenerative air cooling gas to blow cold the bed, in order to meet the needs of the next stage of adsorption work, to avoid the air outlet dew point due to the existence of bed temperature and instability.

The working process

The adsorption

The compressed air containing a large amount of water vapor enters the adsorption tower through the air inlet, passes through the efficient diffusion device, and then diffuses through the adsorption tower.The water vapor is absorbed by the adsorbent as it passes through the adsorption column.The dried compressed air is fed into the air pipe network through the outlet.

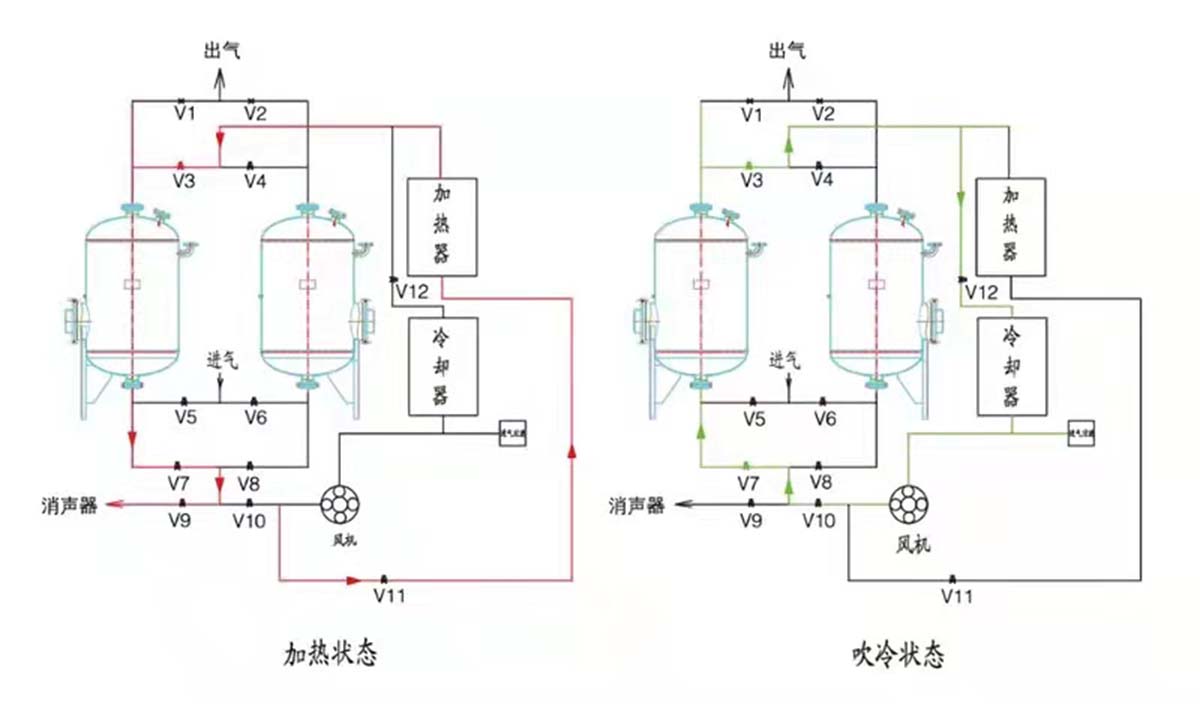

Heating regeneration stage

In one tower adsorption at the same time the other tower regeneration process.Before that, the pressure in the tower will be lowered to atmospheric pressure by the pressure relief system.

Use ambient air for regeneration

First, a blower draws in ambient air and pressurizes it to the regeneration pressure, then a heater heats the air further to the regeneration temperature (~ 130 ° C).Under the continuous action of the blower, the hot air flows into the adsorption bed, and the desaturation and evaporation of the hot air are used to regenerate and dry the adsorbent.

Purge the stage

At the end of the heating process, the cold blowing stage is also carried out with ambient air.A unique way of cold blowing the closed water cooling system, through the combination of the valve action to form a closed loop system, fan as a driving force power cycle, make the hot air inside the adsorption tower continuous heat exchange with water cooler, cold air cooled again into the absorption tower, take away the quantity of heat of adsorbent, the temperature of the lower the temperature of the best adsorbent.

Technical indicators

| Air handling capacity | 6 ~ 500Nm3/min |

| Working pressure | 0.5 ~ 1.0mpa (not in this range can be customized) |

| Dew point | -40 ~ -60℃ |

| Inlet temperature | ≤45℃ |

| Ambient temperature | ≤45℃ |

| Gas consumption | zero gas consumption |

| Overall pressure drop | ≤ 0.03mpa |

| Standard working cycle | 6 ~ 8h |

| Power supply | AC380V / 50 hz |

| Installation method | integral skid without foundation installation |

Product features

● Long life of desiccant, normal use of desiccant life can be up to 5 years.

● Large diameter tower, slow gas flow rate, long adsorption contact time, high adsorption efficiency.

● Adjustable heater power, flexible choice of other heating medium, such as steam heating.

● Reliable high temperature resistant double eccentric pneumatic valve, service life, long maintenance cycle.

● Automatic Siemens PLC control, parameters can be modified and adjusted.

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for China OEM Air Drying Equipment Quotes – JXG type blast regenerative air dryer – Juxian , The product will supply to all over the world, such as: Salt Lake City, Somalia, Kenya, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!